I had intended for the aero bodywork project to be a simple "bolt on" approach which would require no (permanent) chassis modifications.

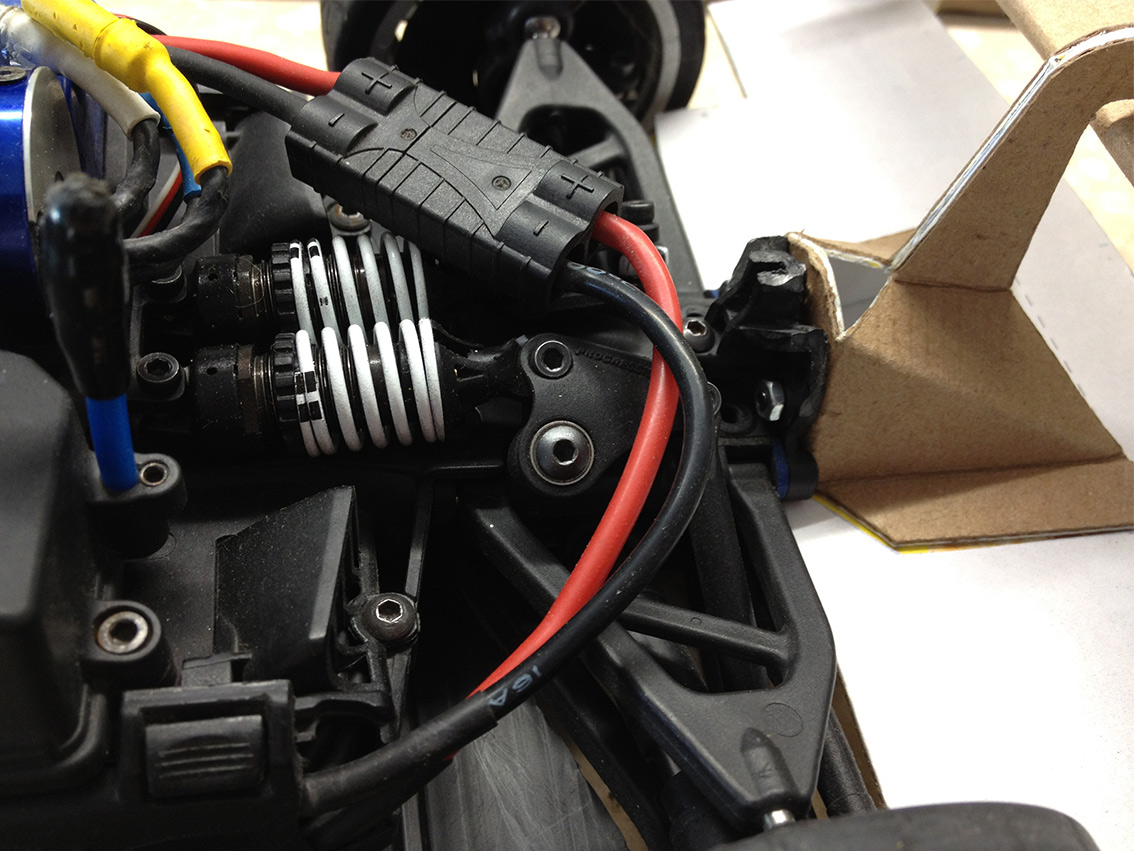

This approach imposed that many standard hard-points of the chassis be retained. The motor, the receiver radio box, antennae, the bumper... these all define the minimal boundaries of the bodywork. A place where this has probably the biggest impact on the effectiveness and appearance of the prototype style bodywork is the rear bulkhead.

The standard bulkhead is tall, with wide-spaced body-post blocks oriented for coupe and hatchback bodywork. For a low-slung prototype, the body posts will need to be removed, as would the hatchback specific diffuser support structures... The bulkhead is held on by five screws and could easily be swapped between a "hatchback" body setup and a "prototype" setup, each optimized for their specific use.

At first just the body-post sockets were removed... but this still forced the rear bodywork to be very far above the components it should be clinging to.

Chopping the bulkhead down further allowed for a much more compact component. The equally-compact wing-strut and diffuser carrier bolts on with three screws now instead of four, but the result is a reduction in rear deck height of about half in the critical area leading toward the rear wing. This results in a huge increase in volume of air getting the wing and in potential downforce generated.

The bodywork will require a total redesign from the mid-section on through to the tail, as well as a rework of the underbody aero (splitter and diffuser) to balance the newly-gained rear downforce. This is all a very good thing.